Push To Lock Fittings

Push To Lock Fittings Specification

- Shape

- Straight, Elbow, Tee, Cross, Bulkhead, Reducer, Branch, etc.

- Head Code

- Hexagon, Round, Square

- Surface Treatment

- Nickel Plated, Polished, Anodized

- Working Mediums

- Air, Water, Gas, Vacuum

- Plating

- Nickel

Push To Lock Fittings Trade Information

- Minimum Order Quantity

- 100 Units

- Delivery Time

- 2 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia

About Push To Lock Fittings

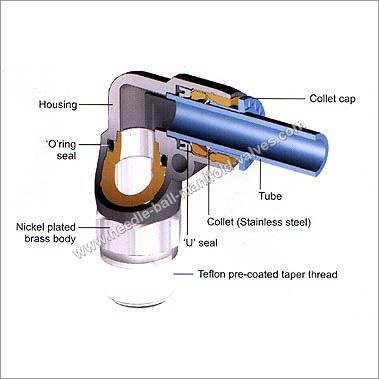

Our vast market understanding and industry experience enable us manufacture, export and supply a broad assortment of Brass Compression Fitting. This fitting is used in various fuel lines, compressed air lines and pneumatic circuits for making leak proof connections. Our technical experts make use of modern techniques and the finest quality raw material to manufacture offered fitting in sync with global market standards. Additionally, this Brass Compression Fitting can be availed from us in numerous specifications at market leading price.

Features:

- Resistant to rust

- Excellent tolerance

- Light weight

- Leakage proof fitting

- Quickest and Easiest to gather tubing into the PUSH-TO-LOCK Fittings, simply push the tubing into fitting upto the base and watertight association is made.

- Quickest and Easiest to Dis pushing so as to gather is accomplished discharge neckline. This separates the gripper collet and permits the tubing to be hauled out. Its that basic.

- Push its associated; push/draw its disengaged.

No Tubing Twist

The gripper collect and tubing are allowed to pivot inside of the fitting body. In the event that the tube is turned, it wont contort or debilitate.

Swing Clearance Problems Eliminated

Elbows and tees are accessible with a basic swivel at the male channel end. This permits the funnel string to be fixed without turning the elbow or tee. It additionally allows the channel string to be fixed without stress over where the flip side of the fitting will point, as it can be turned into position after the funnel string is tight.

Working Pressure and Temperature Ranges

Zero to 60oC at up to 10 Bar. Vacuum applications are reliant upon temperature and kind of tubing being utilized.

Assembly Instructions

Cut Nylon, Polyurethane and Polyethylene tubing decisively utilizing Pioneer SQUARE CUT tube cutter. Metal tubing ought to be cut unequivocally and be free of burrs. Embed end of tubing until it bottoms in fitting. Discouraging the discharge catch permits the tubing to be uprooted.

Ordering Information

To Order, basically determine inventory number for arrangement and size wanted.

Advertising and Technical Services

Wide Dealer system will help you in selecting the most proper fittings and tubing for your application, furthermore make them accessible to you at whatever point your need emerges. Progressing Research and Development continually endeavoring to enhance the item to meet more stringent conditions. (Henceforth item arrangements and determinations might change intermittently)

Effortless Installation and Quick Connect Technology

Push to Lock Fittings utilize a tool-free mechanism that enables rapid connection and disconnection of tubing. The quick connect/disconnect design minimizes downtime and streamlines maintenance, making them a preferred choice in pneumatic systems and water supply lines. No specialized skills or equipment are required, ensuring that installation can be performed swiftly by operators at any experience level.

Versatile Material Range for Enhanced Application

These fittings are constructed from high-quality brass, stainless steel, PBT, and plastics to cater to diverse application requirements. They are suitable for varying port sizes and available in shapes like straight, elbow, tee, and more. Surface finishes such as nickel plating, polishing, and anodizing enhance corrosion resistance, making them durable for industrial automation and harsh environments.

FAQs of Push To Lock Fittings:

Q: How are Push to Lock Fittings installed without tools?

A: Push to Lock Fittings feature a tool-free mechanism where tubing can be simply inserted into the fitting until it locks securely in place. Disconnection is equally easyjust press the release collar to withdraw the tubing, eliminating the need for additional wrenches or equipment.Q: What materials are available for Push to Lock Fittings, and why choose them?

A: These fittings are offered in brass, stainless steel, PBT, and quality plastics, each selected for their strengths. Brass and stainless steel provide superior durability and corrosion resistance, while engineered plastics and PBT offer lightweight performance for less demanding applications.Q: When should you select different seal materials for your fittings?

A: Seal materialsNBR, EPDM, and FKMshould be chosen based on the working medium and environment. NBR is best for air and water, EPDM excels in water and steam, and FKM is recommended for chemical and high-temperature uses, ensuring reliable sealing under various conditions.Q: Where can Push to Lock Fittings be used effectively?

A: They are ideal for applications such as pneumatic systems, industrial automation, and water lines. Their compatibility with air, water, gas, and vacuum makes them versatile for factories, machine installations, and even water treatment plants.Q: What process ensures leak-proof performance in these fittings?

A: The fittings use precision-engineered sealing with NBR, EPDM, or FKM materials that compress against the tubing as it is inserted, preventing leaks. Their compliance with ISO and RoHS standards further assures consistent quality and performance.Q: What are the key benefits of using quick connect Push to Lock Fittings?

A: These fittings provide rapid, reliable connections, reduce installation time, and minimize maintenance costs. Their wide material and size range, robust sealing, and compliance with international standards make them a safe and efficient solution for diverse industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Pipe Fittings Category

Brass Compression Fitting Union

Minimum Order Quantity : 1 Unit

Usage : Industries

Warranty : Yes

Product Type : Brass Pipe Fittings

Material : Brass Pipe Hex Nipple

Brass Pipe Hex Nipple

Minimum Order Quantity : 10 Pieces

Usage : Industries

Warranty : Yes

Product Type : Brass Pipe Fittings

Material : Brass Pipe Hex Nipple

Brass 4 Way Female Fittings

Minimum Order Quantity : 10 Pieces

Usage : Industries

Warranty : Yes

Product Type : Brass Pipe Fittings

Material : Brass Pipe Forging Plug

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese