Flare Connectors

Flare Connectors Specification

- Shape

- Straight

- Head Code

- Hexagon

- Surface Treatment

- Polished

- With Rings

- No

- Working Mediums

- Air, Water, Oil

- Plating

- Nickel Plated

About Flare Connectors

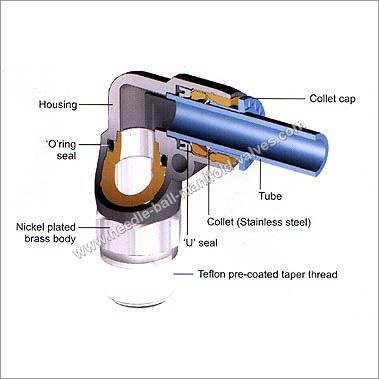

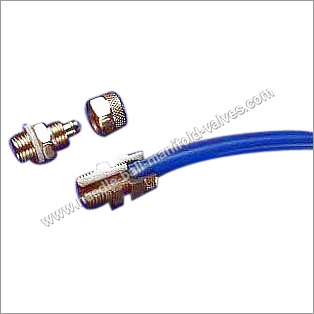

Relying on our expertise in this domain, we are successfully manufacturing and exporting an excellent range of Flare Connectors. These connectors are specifically designed for ensuring an unrestricted flow and protection against pressure drops in systems. Carefully machined with utmost perfection using best quality materials, these Flare Connectors are stringently tested on various standard parameters. We offer these connectors to clients at very reasonable prices.

Features:

- Eliminates the possibility of seepage by porosity

- Assure tight leak-proof joints

- Smooth interior finish

Superior Material and Reliable Construction

Manufactured from high-quality brass and finished with nickel plating, these flare connectors boast excellent corrosion resistance. Each connector undergoes a meticulous polishing process to ensure both aesthetic appeal and long-term durability, making them suitable for demanding hydraulic and pneumatic systems.

Flexible Application Across Multiple Industries

With pressure ratings up to 400 bar and compatibility with mediums such as air, water, and oil, these connectors support a wide range of industrial uses. Adhering to ISO and DIN standards, they ensure consistent, reliable performance in critical installations for exporters, manufacturers, suppliers, and traders.

FAQs of Flare Connectors:

Q: How do you install brass flare connectors with threaded connections?

A: Install brass flare connectors by threading them onto compatible pipes or tubes, ensuring the hexagonal head is tightened securely. Use a proper wrench for this process to prevent damage and guarantee a leak-resistant seal.Q: What is the benefit of using nickel-plated flare connectors in hydraulic and pneumatic applications?

A: Nickel plating enhances corrosion resistance, extends service life, and maintains a polished finish. This makes the connectors ideal for hydraulic and pneumatic applications where exposure to moisture or aggressive media is frequent.Q: When should I choose 1/8" to 1/2" inch flare connectors for my system?

A: Select connectors within this size range when your piping or tubing system requires highly reliable, compact, and pressure-resistant joints for air, water, or oil mediums. Their versatility fits the needs of most hydraulic and pneumatic line installations.Q: Where can these flare connectors be sourced in India?

A: These connectors are available through exporters, manufacturers, suppliers, and traders across India. Many industrial supply companies stock a variety of sizes that meet ISO/DIN standards for immediate dispatch.Q: What is the process for achieving corrosion resistance in these brass connectors?

A: Corrosion resistance is achieved through the use of high-quality brass, followed by surface polishing and nickel plating. These treatments form a protective barrier against rust and chemical wear over time.Q: How are these connectors used in hydraulic and pneumatic systems?

A: They are used to join pipes or tubes, forming a leak-proof connection that withstands high working pressures. Their hexagon head simplifies tightening and loosening during maintenance or installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Pipe Fittings Category

Push To Lock Fittings

Price Range 50.00 - 200.00 INR

Minimum Order Quantity : 100 Units

Surface Treatment : Other, Nickel Plated, Polished, Anodized

Working Mediums : Other, Air, Water, Gas, Vacuum

Plating : Other, Nickel

Shape : Other, Straight, Elbow, Tee, Cross, Bulkhead, Reducer, Branch, etc.

Air-O-Fit Brass Push On Fittings

Price Range 50.00 - 200.00 INR

Minimum Order Quantity : 100 Units

Surface Treatment : Other, Polished

Working Mediums : Other, Air, Water

Plating : Other, Nickel Plated

Shape : Other, Straight, Elbow, Tee, Reducer

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese