सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² डबल फà¥à¤°à¥à¤² पà¥à¤°à¥à¤· पाà¤à¤ª वà¥à¤²à¥à¤¡ à¤à¤¨à¥à¤à¥à¤à¤°

Price 35 आईएनआर/ Unit

सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² डबल फà¥à¤°à¥à¤² पà¥à¤°à¥à¤· पाà¤à¤ª वà¥à¤²à¥à¤¡ à¤à¤¨à¥à¤à¥à¤à¤° Specification

- प्रॉडक्ट टाइप

- मटेरियल

- टाइप करें

- शेप

- तकनीक

- सतह का उपचार

- स्टैण्डर्ड

- बाहरी व्यास

- 1/8 to 2 (3 mm to 50 mm) or as specified

- लम्बाई

- Custom lengths available

- अंदर का व्यास

- Customizable as per requirement

- दीवार की मोटाई

- As per standard or customized

- टेन्साइल स्ट्रेंथ

- 515 MPa minimum (for SS 316)

- ग्रेड

- SS 304 / SS 316 / SS 316L

- साइज

- 1/8 to 2 NPT / BSPT / BSP / Metric Threads

- रंग

- Metallic Silver

सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² डबल फà¥à¤°à¥à¤² पà¥à¤°à¥à¤· पाà¤à¤ª वà¥à¤²à¥à¤¡ à¤à¤¨à¥à¤à¥à¤à¤° Trade Information

- Minimum Order Quantity

- 10 Units

- आपूर्ति की क्षमता

- 100 प्रति महीने

- डिलीवरी का समय

- 7 दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² डबल फà¥à¤°à¥à¤² पà¥à¤°à¥à¤· पाà¤à¤ª वà¥à¤²à¥à¤¡ à¤à¤¨à¥à¤à¥à¤à¤°

Stainless Steel Double Ferrule Male Pipe Weld Connector

We have marked a remarkable position in the industry by manufacturing, exporting and supplying a broad array of Male Pipe Weld Connector. This connector is efficiently manufactured by utilizing optimal grade metal alloy with the help of advanced technology under the stern observation of our experts. Offered connector is used for pipe and tube fitting applications in various industries. In addition, this Male Pipe Weld Connector can be availed from us in numerous sizes at industry leading price.

Features:

- Robust built

- Resistant to corrosion

- Dimensional accuracy

- High strength

METRIC

| Part No. | Tube O.D. T mm |

Pipe Weld Size P mm |

E mm |

h mm | H mm | F | G | l1 |

| PMWC-M03-02 | 3 | 1/8 | 2.4 | 12 | 12 | 12.9 | 15.3 | 9.7 |

| PMWC-M04-02 | 4 | 1/8 | 2.4 | 12 | 12 | 13.7 | 16.1 | 9.7 |

| PMWC-M06-02 | 6 | 1/8 | 4.8 | 14 | 14 | 15.3 | 17.7 | 9.7 |

| PMWC-M06-04 | 6 | 1/4 | 4.8 | 14 | 14 | 15.3 | 17.7 | 14.2 |

| PMWC-M08-02 | 8 | 1/8 | 5.1 | 15 | 16 | 16.2 | 18.6 | 9.7 |

| PMWC-M08-04 | 8 | 1/4 | 6.4 | 15 | 16 | 16.2 | 18.6 | 14.2 |

| PMWC-M08-08 | 8 | 1/2 | 6.4 | 22 | 16 | 16.2 | 18.6 | 19 |

| PMWC-M10-04 | 10 | 1/4 | 7.1 | 18 | 19 | 17.2 | 19.5 | 14.2 |

| PMWC-M10-06 | 10 | 3/8 | 7.9 | 18 | 19 | 17.2 | 19.5 | 14.2 |

| PMWC-M10-08 | 10 | 1/2 | 7.9 | 22 | 19 | 17.2 | 19.5 | 19 |

| PMWC-M12-04 | 12 | 1/4 | 7.1 | 22 | 22 | 22.8 | 22 | 14.2 |

| PMWC-M12-06 | 12 | 3/8 | 9.5 | 22 | 22 | 22.8 | 22 | 14.2 |

| PMWC-M12-08 | 12 | 1/2 | 9.5 | 24 | 22 | 22.8 | 22 | 19 |

| PMWC-M15-08 | 15 | 1/2 | 11.9 | 24 | 25 | 24.4 | 22 | 19 |

| PMWC-M16-08 | 16 | 1/2 | 12.7 | 24 | 25 | 24.4 | 22 | 19 |

| PMWC-M18-08 | 18 | 1/2 | 13.5 | 27 | 30 | 24.4 | 22 | 19 |

TOP IMPERIAL

| Part No. | Tube O.D. T | Pipe Weld Size P |

E Min |

h | H | F | l | L | |

| in | Nom | O.D. | in | in | |||||

| PMWC-02-02 | 1/8 | 1/8 | 10.3 | 2.28 | 7/16 | 7/16 | 12.7 | 23.87 | 31.24 |

| PMWC-03-02 | 3/16 | 1/8 | 10.3 | 3.04 | 7/16 | 1/2 | 13.71 | 24.63 | 31.24 |

| PMWC-04-02 | 1/4 | 1/8 | 10.3 | 4.82 | 1/2 | 9/16 | 15.24 | 25.4 | 32.76 |

| PMWC-04-04 | 1/4 | 1/4 | 13.7 | 4.82 | 9/16 | 9/16 | 15.24 | 30.48 | 37.84 |

| PMWC-05-02 | 5/16 | 1/8 | 10.3 | 5.08 | 9/16 | 5/8 | 16.25 | 26.67 | 37.03 |

| PMWC-05-04 | 5/16 | 1/4 | 13.7 | 6.35 | 9/16 | 5/8 | 16.25 | 31.24 | 38.6 |

| PMWC-06-04 | 3/8 | 1/4 | 13.7 | 7.11 | 5/8 | 11/16 | 16.76 | 32.51 | 39.87 |

| PMWC-06-06 | 3/8 | 3/8 | 17.1 | 7.11 | 11/16 | 11/16 | 16.76 | 32.51 | 39.87 |

| PMWC-06-08 | 3/8 | 1/2 | 21.3 | 7.11 | 7/8 | 11/16 | 16.76 | 38.86 | 43.23 |

| PMWC-08-06 | 1/2 | 3/8 | 17.1 | 10.41 | 13/16 | 7/8 | 22.86 | 33.27 | 43.43 |

| PMWC-08-08 | 1/2 | 1/2 | 21.3 | 10.41 | 7/8 | 7/8 | 22.86 | 38.86 | 49.02 |

| PMWC-08-12 | 1/2 | 3/4 | 26.67 | 10.41 | 1-1/16 | 7/8 | 22.86 | 40.38 | 50.54 |

| PMWC-10-08 | 5/8 | 1/2 | 21.3 | 12.7 | 15/16 | 1 | 24.38 | 38.66 | 49.02 |

| PMWC-12-12 | 3/4 | 3/4 | 26.67 | 15.74 | 1-1/16 | 1-1/8 | 24.38 | 40.38 | 50.54 |

| PMWC-16-16 | 1 | 1 | 33.4 | 22.35 | 1-3/8 | 1-1/2 | 31.24 | 50.03 | 62.23 |

Exceptional Pressure and Corrosion Resistance

Designed for challenging industrial settings, this connector withstands working pressures up to 6000 psi (413 bar) and provides outstanding corrosion resistance. Whether installed in oil & gas, chemical, pharmaceutical, or hydraulic systems, it ensures secure, long-term connections even in harsh environments.

Precision Engineering and Flexible Customization

Manufactured using advanced cold forming and CNC machining techniques, our connectors meet ASTM A276 and A182 standards. Options for inside diameters, wall thickness, outer diameters, and lengths allow for tailored solutions to specific project requirements, ensuring seamless system integration.

Reliable Fit for Diverse Applications

Featuring a double ferrule tube end and a male pipe weld thread (NPT/BSPT/BSP/Custom), this connector is suitable for both new installations and maintenance in instrumentation, process piping, or other specialty systems. Its robust tensile strength (minimum 515 MPa for SS 316) and high-grade surface finish offer lasting reliability and performance.

FAQs of Stainless Steel Double Ferrule Male Pipe Weld Connector:

Q: How does the double ferrule system benefit my instrumentation or process piping setup?

A: The double ferrule system provides a leak-proof seal by gripping the tubing securely without deforming it, enhancing reliability in high-pressure applications. This ensures process safety and minimizes maintenance in critical environments such as oil & gas, chemical plants, and pharmaceuticals.Q: What customization options are available for the inside diameter and lengths of the connector?

A: We offer a full range of customizations for inside diameter, outer diameter (1/8 to 2 inches or 3 mm to 50 mm), wall thickness, and overall length, allowing you to match precise specifications for your application. You can request these customizations based on your projects unique requirements.Q: When should I choose between NPT, BSPT, BSP, or custom thread types?

A: The selection depends on your piping standards and regional or system compatibility. NPT threads are common in North America, while BSPT/BSP are more prevalent internationally. Custom threads are available for special requirements, ensuring optimal fit within your installation.Q: Where can this connector be used?

A: This stainless steel connector is suitable for a wide range of industries, including oil & gas, process piping, chemical, pharmaceutical, hydraulic, and instrumentation systems, particularly where high pressure and superior corrosion resistance are crucial.Q: What processes are used in manufacturing these connectors?

A: Our connectors are produced using cold forming and CNC machining for high dimensional accuracy. They are finished with polishing, passivation, or electrolytic treatments to enhance corrosion resistance and surface smoothness, meeting stringent quality standards (ASTM A276/A182).Q: How do the corrosion resistance and surface treatments benefit usage in harsh environments?

A: Stainless steel grades SS 304, SS 316, and SS 316L offer superior corrosion resistance, while polished, passivated, or electrolytic surface treatments add further protection. This ensures the connectors remain reliable and durable even when exposed to aggressive chemicals, high humidity, or other corrosive factors.Q: What are the main benefits of choosing this male pipe weld connector for industrial systems?

A: The main benefits include high pressure tolerance, leak-proof double ferrule connections, exceptional durability against corrosion, flexible customization, and suitability for strict process requirements, ensuring long-term, trouble-free performance in demanding industrial environments.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in स्टेनलेस स्टील डबल फेर्यूल फिटिंग Category

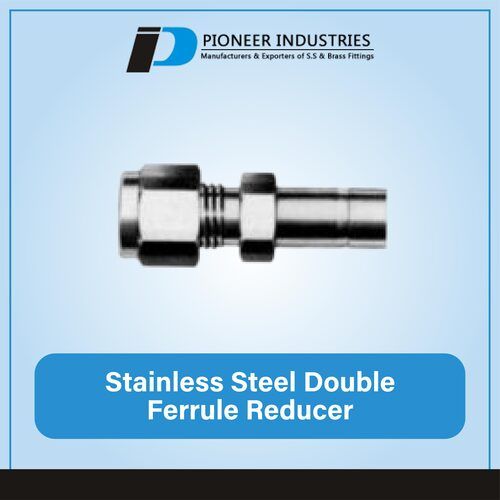

स्टेनलेस स्टील डबल फेरूल रिड्यूसर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 10

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

रंग : Silver

ग्रेड : SS316

स्टेनलेस स्टील डबल फेरूल महिला कनेक्टर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 10

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

रंग : Silver

ग्रेड : 304/316 Stainless Steel

स्टेनलेस स्टील डबल फेरूल पुरुष एडाप्टर

माप की इकाई : , , यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 10

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

स्टेनलेस स्टील डबल फेरूल बैक फेरूल

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 50

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese