Mini Needle Valves

Mini Needle Valves Specification

- Power

- Manual

- Media

- Water

- Packing Type

- Plastic or Cardboard Box Packaging

- Compliance

- ISO 9001:2015 Certified

- Mounting

- Panel Mounting Option Available

- Flow Control

- Precise Flow Regulation

- Body Finish

- Polished Finish

- End Connections

- Male/Female or Male/Male Threads

- Orifice Size

- 1.5 mm (standard)

- Seal Type

- PTFE or NBR Gasket

- Handle Type

- Knurled Round Handle for Fine Adjustment

Mini Needle Valves Trade Information

- Minimum Order Quantity

- 50 Units

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia

About Mini Needle Valves

Owing to the competency and knowledge of our deft professionals, we are offering a comprehensive array of Needle Valve. Our skilled professionals make use of the finest quality raw material and advanced technology to manufacture this valve in accordance with set industry norms. It is used to allow precise regulation of flow of liquid and fluid. In addition, this Needle Valve is ideal for connecting pipelines in various chemical, oil, pharmaceutical and other allied industries.

Features:

- Corrosion resistance surface finish

- Sturdiness

- Dimensional accuracy

- Easy installation

Advantages

- The pioneer Needle valves are equipped with metal to metal seats with fine strung screwdown. This empowers positive fixing up to the limit of the valve.

- Pioneer Needle valves are produced using manufactured metal body with SS304 axle and PTFE washer which gives augmented administration life. All valves are coated with chrome finish.

Working pressure ranges

- Valves are designed to withstand up to 150 PSI working pressure, unless otherwise noted.

- Needle Valves Installation Instructions

- All Needle valves should always be installed with the pressure against the seat. Or the arrow shown on body.

- Availability of Sizes

- Available in 1/4 BSP, 3/8 BSP, 1/2 BSP sizes and in form of Male to Male, Female to Female, Male to Tube, Female to Tube.

Engineered for Precision Flow Control

Mini Needle Valves offer unparalleled control over fluid flow, allowing precise adjustments for laboratory, process, and research applications. The 1.5 mm standard orifice and round knurled handle are engineered to give users finely grained control, reducing the risk of overcorrection or leaks. Finished with a polished exterior for corrosion resistance, these valves integrate seamlessly into a variety of systems and panel-mounted setups.

Trusted Sealing and Manual Operation

Every Mini Needle Valve is equipped with a PTFE or NBR gasket, ensuring secure sealing that withstands frequent operation and prevents leaks. The manual power operation, coupled with an ergonomically designed handle, delivers both robustness and tactile precision. Designed for compatibility with water, these valves are a reliable choice for controlled, hands-on fluid regulation.

Compliance and Quality Assurance

Manufactured under an ISO 9001:2015 certified quality management system, these Mini Needle Valves meet stringent standards suited to diverse industrial needs. Each unit is packaged securely in either plastic or cardboard boxes, with panel mounting options available for easy integration into existing setups. Exporters, suppliers, and manufacturers in India can trust these valves for consistent, high-quality performance.

FAQs of Mini Needle Valves:

Q: How do I install a Mini Needle Valve with panel mounting option?

A: To install a Mini Needle Valve with panel mounting, insert the valve into the prepared panel cutout, secure it using the provided mounting hardware, and ensure the end connections are properly threaded (male/female or male/male) for leak-proof integration into your system.Q: What is the main benefit of using a Mini Needle Valve for water applications?

A: Mini Needle Valves provide precise flow regulation, allowing for controlled and gradual adjustment of water flow, making them ideal for sensitive applications in laboratories, research facilities, and industrial settings.Q: When should I choose a Mini Needle Valve with a 1.5 mm orifice?

A: A 1.5 mm orifice is standard for Mini Needle Valves and is best suited for applications that require fine control over small to moderate flow rates, such as analytical processes and instrumentation lines.Q: Where can these Mini Needle Valves be utilized effectively?

A: These valves are commonly used in laboratories, industrial plants, water treatment facilities, and anywhere precise water flow adjustment is essential. They are suitable for exporters, suppliers, and manufacturers in India and globally.Q: What materials are the gaskets made from, and how do they affect usage?

A: The gaskets are made from PTFE or NBR, both offering excellent resistance to water and chemicals, ensuring a reliable seal and long-term durability, even with frequent operational cycles.Q: How do I achieve fine adjustment with the Mini Needle Valve?

A: Use the knurled round handle to turn the needle stem gradually, allowing for smooth and finely tuned manual regulation of water flow without abrupt changes or overcorrection.Q: What ensures the leak-resistance of these Mini Needle Valves?

A: Leak-resistance is ensured by the use of precision machining, polished body finish, and the inclusion of high-quality PTFE or NBR gaskets at the sealing interface, effectively preventing fluid escape during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Valve Category

SS Needle Valves H B Series

Minimum Order Quantity : 10 Pieces

Product Type : Needle Valve

Color : yellow

Usage : Pneumatic and Hydraulic

Pressure : Low Pressure

Material : Brass

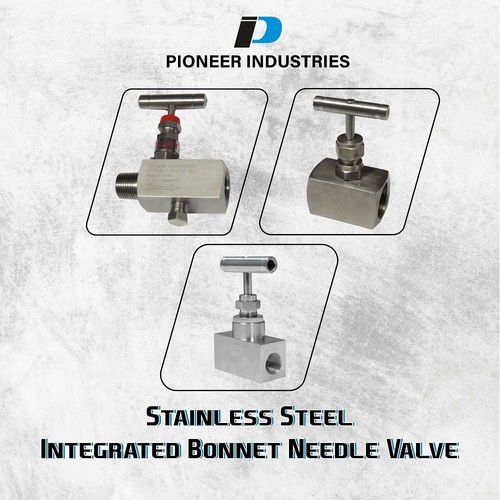

Stainless Steel Integrated Bonnet Needle Valve

Minimum Order Quantity : 10 Units

Product Type : Stainless Steel Needle Valves

Color : steel

Usage : Industries

Stainless Steel Integrated Bonnet Needle Valve Male to female

Product Type : Stainless Steel Needle Valves

Color : steel

Usage : Industries

Pressure : Medium Pressure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese