SS Needle Valves H B Series

SS Needle Valves H B Series Specification

- Connection

- Thread

- Temperature of Media

- 50 Celsius (oC)

- Usage

- Pneumatic and Hydraulic

- Material

- Brass

- Surface Treatment

- Plating

- Product Type

- Needle Valve

- Pressure

- Low Pressure

- Color

- yellow

- Power

- Manual

- Media

- Gas

- Port Size

- 1/4" to 4"

- Weight

- 200 Grams (g)

SS Needle Valves H B Series Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Africa, Central America, South America, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About SS Needle Valves H B Series

Our company is the most promising manufacturer and exporter of a wide range of SS Needle Valves. These valves are high in demand for sugar & distillery plants, chemical plants, steel manufacturing industry, water treatment plants, refineries, petrochemical plants, pulp & paper mills and pharmaceutical industry. Ideal for use with various process systems and analytical instrumentation, these SS Needle Valves are stringently tested on various standard quality parameters.

Features:

- Rugged construction

- Can sustain high pressures

- Long life span

SS Needle Valves H B Series

Specification

- Hex Bar stock Body development.

- It has an optional mounting panel with straight or angle pattern.

- Metal to Metal or Stellited seats. Stem strings Rolled and hard plated and tie stellied (Vee Regulating one piece or non-managing) or non-turning ball tip discretionary.

2 piece Chevron pressed offers zero hole, fixing over traditional pressing outline. - Variety of End associations incorporate "PIONEER" single or twin ferrule tube fittings, Male or Female N. P. T. also, I. S. O., DIN and JIS decreased funnel closes.

- Maximum Working Pressure : 6000 PSI (400 bar) at 200oC. 10000 PSI (700 bar) at 120oC.

100% factory tested.

Data Sheet :

- End Connections- Model No

- Female X Female - PNV-H-S-FF

- Male X Female - PNV-H-S-MF

- Male X Female with Vent - PBB-H-S-MF

Reliable Performance for Gas Applications

Engineered for use in pneumatic and hydraulic systems, the SS Needle Valves H B Series excels in regulating the flow of gas at low pressures. The brass construction ensures longevity and corrosion resistance, making these valves a dependable choice for both industrial and commercial environments. Their compatibility with thread connections and diverse port sizes brings flexibility to a wide range of installations.

Versatile and User-Friendly Design

These needle valves are crafted with user convenience and system efficiency in mind. The manual operation offers precise flow control, while their lightweight (200 grams) and compact form allow for easy integration. With a temperature tolerance of up to 50C and plating surface treatment, they are suitable for various working conditions seen across Indian industries.

FAQs of SS Needle Valves H B Series:

Q: How are SS Needle Valves H B Series typically used in pneumatic and hydraulic systems?

A: These needle valves are used to precisely control the flow of gas in pneumatic and hydraulic circuits, ensuring accurate regulation in low-pressure applications.Q: What materials are SS Needle Valves H B Series constructed from, and how do they benefit users?

A: They are made from high-quality brass with a plated finish, which offers strong resistance to corrosion, ensuring a long lifespan and reliable performance in demanding environments.Q: When should these needle valves be chosen over other valve types?

A: These valves are ideal when precise manual flow control of low-pressure gases is required, especially in systems operating up to 50C and needing threaded connections from 1/4" to 4".Q: Where can I install SS Needle Valves H B Series within my gas distribution system?

A: You can install these valves at any point requiring accurate flow adjustment, such as upstream or downstream control lines, instrument isolation points, and branch circuits within gas delivery infrastructure.Q: What is the process of installing these needle valves?

A: Installation is straightforward: select the correct port size (1/4" to 4"), use the threaded connections for secure attachment, and ensure compatibility with your systems operating pressure and temperature.Q: How does the manual power operation benefit system operators?

A: Manual operation allows operators to make real-time, precise adjustments to the gas flow rate, enhancing safety and process control without complex automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Valve Category

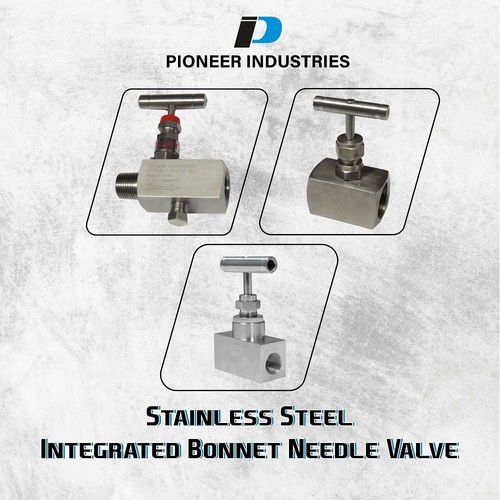

Stainless Steel Integrated Bonnet Needle Valve

Minimum Order Quantity : 10 Units

Color : steel

Usage : Industries

Product Type : Stainless Steel Needle Valves

Stainless Steel Integrated Bonnet Needle Valve Male to female

Color : steel

Usage : Industries

Product Type : Stainless Steel Needle Valves

Pressure : Medium Pressure

Application : Industries

Stainless Steel Integrated Bonnet Needle Valve Tube to tube

Color : steel

Usage : Industries

Product Type : Stainless Steel Needle Valves

Pressure : Medium Pressure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese