Weldable Bulkhead

Weldable Bulkhead Specification

- Product Type

- Weldable Bulkhead

- Material

- Stainless Steel

- Type

- Bulkhead

- Shape

- Cylindrical

- Technique

- Welding

- Surface Treatment

- Polished

- Standard

- ISO

- Outer Diameter

- Standard

- Length

- Standard

- Wall Thickness

- Standard

- Tensile Strength

- High

- Grade

- Standard

- Size

- Standard

- Color

- Silver

- Warranty

- 1 Year

About Weldable Bulkhead

Premium Stainless Steel Construction

This weldable bulkhead is meticulously engineered using high-grade stainless steel for optimal strength and resistance to corrosion. Its polished surface ensures a clean and professional appearance, making it suitable for both utilitarian and visible applications. Designed to meet ISO standards, each component promises consistent quality and exceptional longevity in demanding environments.

Designed for Industrial Versatility

With standard dimensions and a cylindrical shape, the bulkhead offers reliable compatibility with a wide range of piping and containment systems. Its robust design accommodates high tensile stress, making it an excellent choice for industries such as manufacturing, chemical processing, and fluid handling. The versatility of this product streamlines integration into existing frameworks.

FAQs of Weldable Bulkhead:

Q: How is the weldable bulkhead installed in industrial systems?

A: The weldable bulkhead is installed by welding it directly to the required structure or piping system, ensuring a secure and leak-resistant seal. Its standard dimensions and cylindrical shape allow for straightforward integration by qualified professionals using appropriate welding techniques.Q: What are the main benefits of using a stainless steel weldable bulkhead?

A: Stainless steel offers high tensile strength, excellent corrosion resistance, and durability, making it ideal for demanding environments. The polished surface not only enhances appearance but also makes the bulkhead easy to clean and maintain, extending its service life.Q: When is it recommended to use a weldable bulkhead of this type?

A: This type of weldable bulkhead is best deployed in projects where reliable separation, containment, or flow control is essential, particularly in industries like manufacturing, fluid processing, and chemical plants. Its robust construction is suitable for both new installations and upgrades.Q: Where is this weldable bulkhead typically used?

A: It is commonly used in industrial facilities across sectors such as chemical processing, water treatment, oil and gas, and any application requiring a secure, high-strength bulkhead within piping or containment systems.Q: What is the process behind manufacturing these bulkheads?

A: These bulkheads are produced using precise welding techniques that ensure structural integrity and leak prevention. They are crafted from standard-grade stainless steel, polished for a smooth finish, and rigorously tested to meet ISO standards for quality and performance.Q: How does the surface treatment benefit long-term usage?

A: The polished surface treatment enhances the bulkheads resistance to corrosion and wear, ensures minimal buildup of contaminants, and simplifies routine cleaning. This feature contributes significantly to longer-lasting and more reliable operation in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in S.S.Tube Fittings Category

Straight Reducer

Shape : Cylindrical, Other

Material : Stainless Steel

Technique : Machined, Other

Product Type : Other, Straight Reducer

Warranty : 1 Year

Tensile Strength : High Strength

Welding Nipple

Shape : Other, Cylindrical

Material : Other, Steel

Technique : Other, Placeholder

Product Type : Welding Nipple, Other

Warranty : Placeholder

Tensile Strength : Placeholder

EVGE - Swivel Connectors

Shape : Other, Hexagonal

Material : Stainless Steel

Technique : Forged

Product Type : Other, Swivel Connector

Warranty : 1 Year

Tensile Strength : High

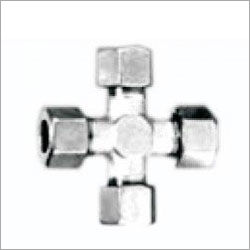

K - Cross Union

Shape : Other, Cross

Material : Stainless Steel

Technique : Forging, Other

Product Type : Other, Cross Union

Warranty : 12 months

Tensile Strength : High

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese