Industrial Check Valves

Industrial Check Valves Specification

- Product Type

- Check Valves

- Color

- Silver

- Sealing

- Soft Seat/Metal Seat

- Available Sizes

- DN15DN300

- End Connection

- Threaded/Flanged/Welded

- Maintenance

- Low

- Body Material

- CF8, CF8M, WCB

- Installation Position

- Horizontal/Vertical

Industrial Check Valves Trade Information

- Minimum Order Quantity

- 1 Piece , , Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 10-20 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Industrial Check Valves

Check Valve

We source and offer check valves, which are mechanical devices, designed for allowing fluid (liquid/gas) to flow through it in only one direction. These two port valves have two openings in the body wherein fluid enters from one end and leave from the other. Our range of check valves is available in different types and is very small, simple, and cost effective. These are ideal options to regulate fluid in chemical and power plants.

Versatile Size and Connection Options

Industrial Check Valves come in a wide size range from DN15 to DN300, fitting diverse pipeline requirements. With selectable end connections including threaded, flanged, and welded configurations, installation adapts to your existing system design, providing flexibility for new projects or retrofitting in established plants.

Durable Materials for Harsh Environments

Manufactured from robust CF8, CF8M, and WCB body materials, these valves offer excellent resistance to corrosion, wear, and industrial stress. This makes them highly suitable for demanding conditions found in chemical processing, water treatment, and utility services, ensuring long service life and durability.

Reliable Sealing for Zero Backflow

With options for soft seat and metal seat sealing, these check valves deliver efficient prevention of reverse flow and leakage. This reliability is crucial for maintaining system integrity and protecting equipment downstream, even under varying temperature and pressure conditions.

FAQs of Industrial Check Valves:

Q: How do Industrial Check Valves prevent backflow in a pipeline system?

A: These valves allow flow in one direction using a simple mechanical structure that closes automatically to block reverse flow, safeguarding equipment and fluid purity across industrial applications.Q: What material choices are available for Industrial Check Valve bodies?

A: The body materials offered are CF8, CF8M, and WCB, each providing distinct benefits in terms of corrosion resistance, durability, and suitability for various fluid types and operating environments.Q: When should I use a soft seat versus a metal seat check valve?

A: Soft seat check valves offer better sealing for lower-pressure, non-abrasive applications, while metal seat options are preferred in high-temperature, high-pressure, or abrasive environments for their longevity and resistance.Q: Where can I install these check valves within my facility?

A: Industrial Check Valves can be installed in both horizontal and vertical pipeline sections. Their flexible connection options make them suitable for integration throughout water supply, chemical processing, and utility networks.Q: What is the process of selecting the right check valve size for my application?

A: Choosing the right size involves matching the valve size (DN15DN300 options) with your pipeline dimensions and the expected flow rates, ensuring proper fit and optimal system performance.Q: What are the maintenance benefits of these Industrial Check Valves?

A: Designed for low maintenance, these valves reduce downtime and operational costs. Their sturdy construction minimizes wear, while reliable sealing lessens the likelihood of frequent repairs or replacements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless steel Valves Category

Stainless Steel 2 Way Ball Valve Female To Female

Minimum Order Quantity : 25 Pieces

Product Type : Ball Valve

Color : Nickel Plating

Pressure : Medium Pressure

Structure : Ball

Stainless Steel Needle Valves

Minimum Order Quantity : 1 Piece , , Piece

Product Type : Needle Valves

Type : Valves

Color : Silver

Pressure : Other, 10,000 PSI (400 bar) PSI

Structure : Needle

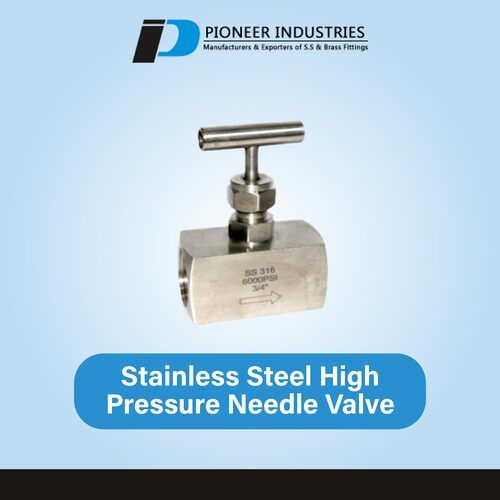

Stainless Steel High Pressure Needle Valve

Minimum Order Quantity : 1 , , Piece

Product Type : Needle Valves

Type : Valves

Color : Silver

Pressure : Medium Pressure

Stainless Steel Needle Valves H P Series

Minimum Order Quantity : 1 Piece , , Piece

Product Type : Needle Valves

Type : Valves

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese