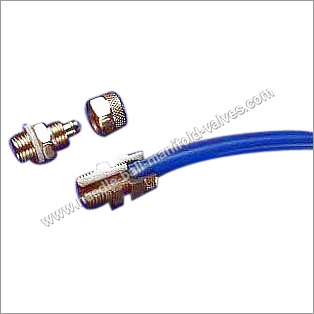

Brass Pipe Coupling

Brass Pipe Coupling Specification

- Material

- Brass

- Product Type

- Brass Pipe Fittings

- Color

- brass

- Usage

- Industries

- Warranty

- Yes

- Pressure Rating

- Upto 16 bar

- Standard

- IS, ASTM, or as per requirement

- Size

- Customizable as per requirement

- Thread Type

- BSP/NPT

- Corrosion Resistance

- Yes

Brass Pipe Coupling Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Packaging Details

- standard

- Main Domestic Market

- All India

- Certifications

- Yes

About Brass Pipe Coupling

Brass Pipe CouplingBrass Pipe Coupling is an inline type connector that is designed to rigidly connect to pipeline without the risk of leakages. It is comes in various diameters and threaded profiles that can be customized as per the applications where it is going to be installed. Brass Pipe Coupling is in high demand as it can be used in corrosive as well as non-corrosive flow systems due to the rust resistant coat over internal as well as external surfaces.

Precision Manufacturing

Every brass pipe coupling is crafted from premium brass and engineered to maintain high tolerance levels. Precision threading (BSP/NPT) ensures a leak-free, secure fit in various industrial installations. Couplings are available in customizable sizes to match system requirements, guaranteeing optimal compatibility.

Corrosion Resistance & Durability

Brass offers inherent resistance to corrosion, making these couplings durable even in aggressive environments. The materials robustness helps maintain performance, reduces maintenance needs, and prolongs operational lifespan. This ensures stability and safety in both liquid and gas transport systems.

Wide Application & Reliable Performance

From waterworks to gas pipelines, HVAC to fire protection, our brass couplings serve a multitude of industries. Each product is tested for up to 16 bar pressure, promising lasting reliability under critical operating conditions. Flexible standards (IS, ASTM, or custom) cover diverse regulatory needs.

FAQs of Brass Pipe Coupling:

Q: How are brass pipe couplings used in industrial applications?

A: Brass pipe couplings connect two sections of pipe, ensuring a leak-resistant and robust joint in both fluid and gas transportation systems. Their easy installation and corrosion resistance make them suitable for water, gas, HVAC, and other industrial pipelines.Q: What are the benefits of using brass pipe couplings over other materials?

A: Brass offers superior corrosion resistance, excellent durability, and a longer service life compared to many other metals. It is less likely to seize or corrode under harsh conditions, making it ideal for consistent, high-pressure use.Q: When should I consider choosing BSP or NPT threading for couplings?

A: The choice between BSP (British Standard Pipe) and NPT (National Pipe Thread) threads depends on regional standards and compatibility with your existing piping system. BSP is widely used in Europe and Asia, while NPT is common in North America. Both threading options can be provided as required.Q: Where are these brass pipe couplings most commonly installed?

A: They are commonly installed in both above-ground and underground fluid and gas transport systems, such as municipal water lines, irrigation networks, industrial processing plants, and HVAC systems, owing to their adaptability and strong sealing capabilities.Q: What is the maximum pressure these couplings can handle?

A: These couplings are rated for operating pressures up to 16 bar, ensuring safe and reliable performance in demanding environments typical in many industrial and utility installations.Q: How can I order couplings in custom sizes or standards?

A: You can specify the required dimensions, threading type (BSP/NPT), and applicable standards (IS, ASTM, or custom) when placing your order. As an exporter, manufacturer, and supplier in India, we accommodate bespoke needs for bulk or specialized requirements.Q: Are brass pipe couplings suitable for both liquid and gas applications?

A: Yes, brass pipe couplings are designed to handle both liquid and gas flows, making them versatile components in a wide range of systems, including water distribution, gas pipelines, and fire protection networks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Pipe Fittings Category

Air-O-Fit Brass Push On Fittings

Price Range 50.00 - 200.00 INR

Minimum Order Quantity : 100 Units

Shape : Other, Straight, Elbow, Tee, Reducer

Surface Treatment : Other, Polished

Head Code : Hexagon

With Rings : Yes

Brass Compression Fittings

Price Range 50.00 - 200.00 INR

Minimum Order Quantity : 100 Units, ,

Shape : Other, Straight, Elbow, Tee, Reducer, Cross, Union, Adapter, Cap, Plug

Surface Treatment : Other, Polished

Head Code : Hexagon

With Rings : Yes

Brass Pipe Male Y Joint Nipple

Shape : Other, Y Joint

Surface Treatment : Other, Polished

Head Code : Male, Other

With Rings : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese