Brass Flare Male Run Tee

Brass Flare Male Run Tee Specification

- Material

- Brass

- Color

- brass

- Usage

- Industries

- Product Type

- Brass Flare Fittings

- Warranty

- Yes

- Thread Type

- NPT/UNF

- Application

- Suitable for refrigeration, air conditioning, gas, and hydraulic systems

- Connection Type

- Flare x Flare x Male NPT

- Size Range

- 1/8" to 3/4"

- Corrosion Resistance

- Excellent

- Pressure Rating

- Up to 3000 psi

Brass Flare Male Run Tee Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 2 Week

- Packaging Details

- standard

- Main Domestic Market

- All India

- Certifications

- Yes

About Brass Flare Male Run Tee

Brass Flare Male Run Tee

Ever since our establishment in 1986, we are engaged in manufacturing and supplying excellent quality Stainless Steel Male Run Tee. It is designed and fabricated at our state-of-the-art facility using highest grade raw materials and latest innovative techniques under proper guidance and supervision of deft professionals. These tees are widely used in plumbing industries for clamping or joining of piping components together. Moreover, this tee is highly appreciated for its efficient functionality and long lasting service life. Offered Stainless Steel Male Run Tee can be availed from us in different models and technical specifications as per requirements and that too at reasonable rate.

Technical Details

|

Code |

Tube O.D. |

Thread |

Code |

Tube O.D. |

|

MM |

INCH |

|||

|

C1203 |

3 |

1/8 |

C1216 |

1/8 |

Robust Brass Construction

Manufactured from premium-quality brass, this flare male run tee ensures reliable performance and outstanding corrosion resistance. It remains unaffected by moisture, gas, or refrigerant exposure, making it an ideal choice for both indoor and outdoor applications in various industries.

High Pressure Endurance

Supporting system pressures up to 3000 psi, the brass flare tee is engineered for secure and dependable operation in refrigeration, air conditioning, gas, and hydraulic installations. It is suitable for demanding environments that require durable and safe connections.

Versatile Connection Compatibility

With connections featuring flare x flare x male NPT and threads compatible with NPT/UNF standards, this tee adapts easily to a wide range of system requirements. Sizes vary from 1/8" to 3/4" for flexible installation in new projects or retrofits.

FAQs of Brass Flare Male Run Tee:

Q: How is the Brass Flare Male Run Tee typically installed?

A: The run tee is installed by connecting the flare ends to suitably flared copper or brass tubing, and the male NPT end to a compatible female-threaded port. Proper tightening and the use of quality flare tools ensure a secure, leak-proof fit.Q: What types of systems commonly use this brass run tee?

A: This fitting is used widely in refrigeration and air conditioning systems, as well as gas and hydraulic pipework, due to its pressure tolerance and resistance to corrosion.Q: When should I choose a brass flare fitting over other materials?

A: Brass is favored when superior corrosion resistance is required, especially where exposure to moisture, corrosive gases, or varied temperatures is likely. Its durability and machinability make it preferable for high-pressure or critical systems.Q: Where can I source the Brass Flare Male Run Tee?

A: You can source these fittings directly from exporters, manufacturers, suppliers, and traders based in India, many of whom offer a broad range of sizes and quick delivery options.Q: What are the benefits of the flare x flare x male NPT configuration?

A: This configuration allows for flexible system integration, enabling easy branching or connection to threaded equipment without additional adapters, simplifying installation and reducing potential leak points.Q: Is the Brass Flare Male Run Tee covered by warranty?

A: Yes, this product comes with a manufacturers warranty. For exact terms, check with your chosen supplier at the time of purchase.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Flare Fittings Category

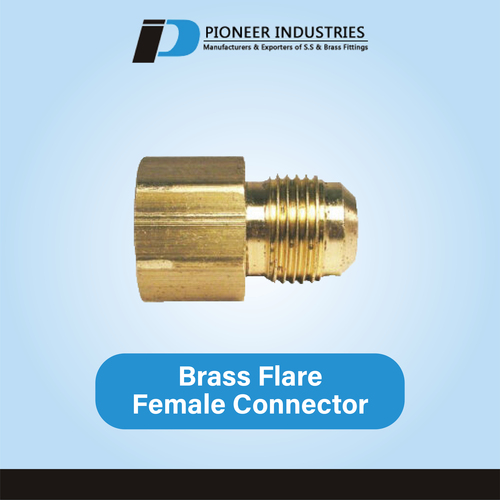

Brass Flare Female Connector

Minimum Order Quantity : 100 Units

Usage : Industries

Material : Brass

Warranty : Yes

Product Type : Brass Flare Fittings

Color : brass

Brass Flare Male Branch Tee

Minimum Order Quantity : 10 Pieces

Usage : Industries

Material : Brass

Warranty : Yes

Product Type : Brass Flare Fittings

Color : brass

Brass Flare Short Union Nut

Usage : Industries

Material : Brass

Warranty : Yes

Product Type : Brass Flare Fittings

Color : brass

Brass Flare Male Elbow

Usage : Industries

Material : Brass

Warranty : Yes

Product Type : Brass Flare Fittings

Color : brass

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese