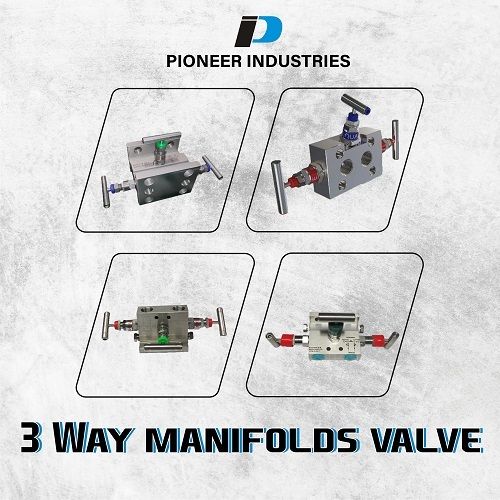

3 Valve Manifolds

Price 200 INR/ Unit

3 Valve Manifolds Specification

- Material

- 316 Stainless Steel, Brass, Carbon Steel, or as specified

- Valve Type

- Manifold Valve

- Connection Type

- Threaded, Flanged, Welded (as per requirement)

- Valve Size

- Standard: 1/2; other sizes available

- Type

- 3 Valve Manifold

- Power

- Manual

- Pressure

- Max 6000 psi (410 bar) at 38C

- Media

- Liquids, gases, vapors (compatible with construction material)

- Port Size

- 1/2 NPT (standard); other connections available on request

- Disc

- Metal

3 Valve Manifolds Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 3 Valve Manifolds

Since our inception in this industry, we have been engaged in manufacturing and exporting an extensive range of 3 Valve Manifolds. These are best suited for aerospace, climate control, electromechnical, filtration, fluid & gas handling and hydraulics. Our highly experienced team uses best quality materials for manufacturing these 3 Valve Manifolds in accordance with industry standards.

Features:

- Rugged design that sustain adverse conditions

- Chemical and acid resistant

- Easy installation

Further Details:

3 Valve Manifolds

Pioneer 3 valve manifolds pipe to pipe (R), pipe to flange (T) and rib to rib (H) intended for uniting framework motivation lines and transmitters. These manifolds comprise of 1/2" NPT(F), channel to rib or rib to spine associations on 54mm (2 1/8") focuses, and of one equalizer valve, two square valves and 2 nos 1/4" NPT(F) cleanse (VENT) associations. These manifolds are tough in development to withstand high weights and temperatures. The manifolds are evaluated for weights as high as 6000 PSI at 200oF or 4000 PSI at 500oF. with PTFE Packing. For a Higher Temperatures Grafoil Packing is utilized.

Data Sheet:

- Type :Model No

- Pipe to Pipe:3 VM - 8 - SS - R

- Pipe to Flange :3 VM - 8 - SS - T

- Flange to Flange : 3 VM - 8 - SS - H

Versatile Installation Options

Our 3 Valve Manifolds accommodate panel, remote, or direct mounting, offering unparalleled flexibility for various instrument setups. Designed to seamlessly fit into your existing systems, these manifolds accept a range of end connectionsscrewed, flanged, or tube fittingsmatching ISO, ANSI, or DIN standards. This versatility ensures compatibility with global industry requirements, providing a universal solution for your fluid control needs.

Premium Materials and High Pressure Capability

Manufactured from robust materials like 316 stainless steel, brass, or carbon steel, our manifolds are designed to withstand harsh industrial environments. With a maximum pressure rating up to 6000 psi (410 bar) at 38C, they are suitable for controlling liquids, gases, and vapors. Designed with either integral forged or screwed bonnets, our products ensure high reliability during demanding operations.

Adaptable for Diverse Applications

Whether used in process plants, refineries, or utility systems, these manifolds are tailored for various media and operational conditions. Choose between PTFE or graphite packings to match your applications temperature demands, and select from inline or direct mount inline orientations for optimal integration. Handle materials are customizablestainless steel, aluminum, or plasticto align with practical and safety requirements.

FAQs of 3 Valve Manifolds:

Q: How are the 3 Valve Manifolds installed in different setups?

A: The manifolds can be mounted directly to the instrument, on a remote bracket, or onto a panel. This wide range of mounting options ensures seamless integration, regardless of your system configuration.Q: What connection types are available for these manifolds?

A: You can choose from threaded (screwed), flanged, or weld-type end connections. All connections adhere to ISO, ANSI, or DIN standards, ensuring global compatibility.Q: When should graphite packing be used instead of PTFE?

A: Graphite packing is recommended for high-temperature environments, while PTFE serves as the standard option for most general applications. The choice depends on your operational temperature requirements.Q: Where are these manifolds typically utilized?

A: They are ideal for industries like petrochemicals, oil & gas, chemical processing, and general industrial instrumentationanywhere precise and reliable pressure control is essential.Q: What is the process for customizing port size or connection type?

A: Port sizes are standard at 1/2 NPT, but other sizes and connection types can be supplied upon request. Simply specify your requirements during the ordering process to receive a product tailored to your system.Q: How does the manifold benefit industrial operations?

A: By combining isolation and equalization functions in one compact unit, these manifolds improve system safety, reduce leak paths, and simplify maintenance in applications involving liquids, gases, or vapors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese